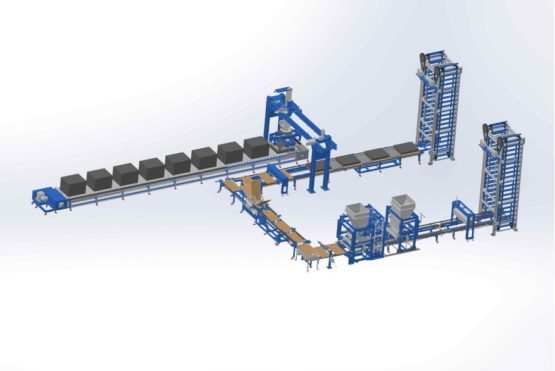

- Pallets are automatic feeded

- Green Product handled by V-Belt conveyor for smooth transport to Elevator

- Pallets are stacked in Elevator

- Product sent to cure chamber automated finger car system

- Cycle time 15-18 secs

- Pallet size - 1300 x 670 x 12/45 - steel/wooden

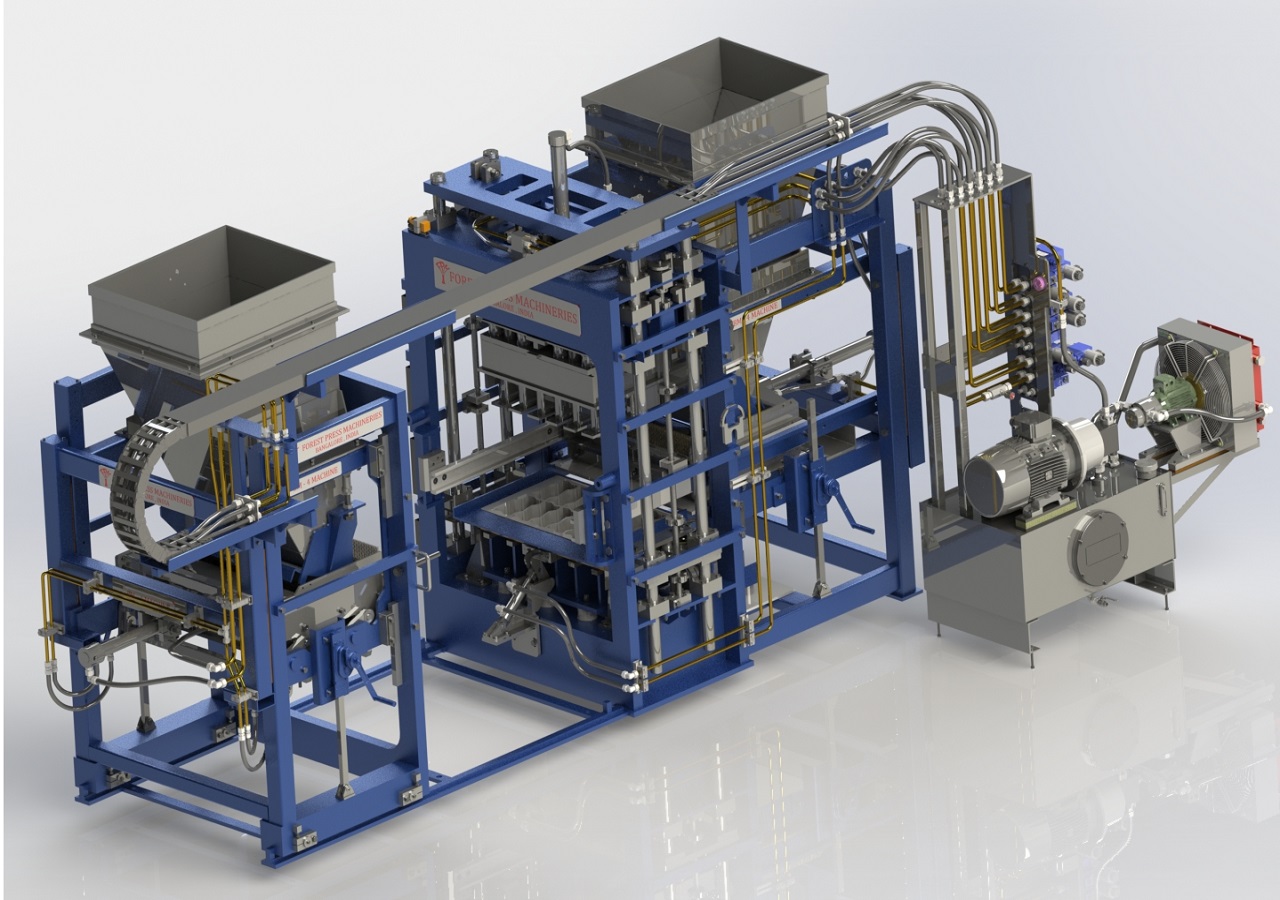

- Synchronized vibration by Servo motor

- Max/min product height 250/25

- Automatized packing system can be used

- To avoid human delays

- U type of system to minimize shed area

- Green product & Dry product can be handled separately

- Flying bucket concrete system

- Agitator for fast filling

- Multicolored dosing

Main Assembly

- Base Mix

- Face Mix

- V-Belt conveyor

- Stone Brush

- Elevator

- Finger car

- Curing Chamber

- Air circulation system

- Lowerator

- Latch Conveyor

- Board Scrapper

- Board Brush

- Pallet turner

- Hydraulic cuber

- Out Put Frame Conveyor

- Cross Conveyor

- Board Hopper

- Board feeder

- Oil spray system

- Board Stopper

Product Capacity

|

|

|

No 10hr@85% |

Area sq m |

| Block |

400 x 200 x 200 |

9 |

13770 |

1102 |

|

400 x 200 x 150 |

12 |

18360 |

1469 |

|

400 x 200 x 100 |

18 |

27540 |

2203 |

| UNI paver |

225 x 112.5 |

25 |

38250 |

968 |

| Rectangular |

200 x 100 |

30 |

46000 |

920 |