Product Capacity

|

|

|

No 10hr@85% |

Area sq m |

| Block |

400 x 200 x 200 |

12 |

20400 |

1632 |

|

400 x 200 x 150 |

16 |

27200 |

2176 |

|

400 x 200 x 100 |

24 |

40800 |

3264 |

| UNI paver |

225 x 112.5 |

35 |

59500 |

1506 |

| Rectangular |

200 x 100 |

48 |

71400 |

1428 |

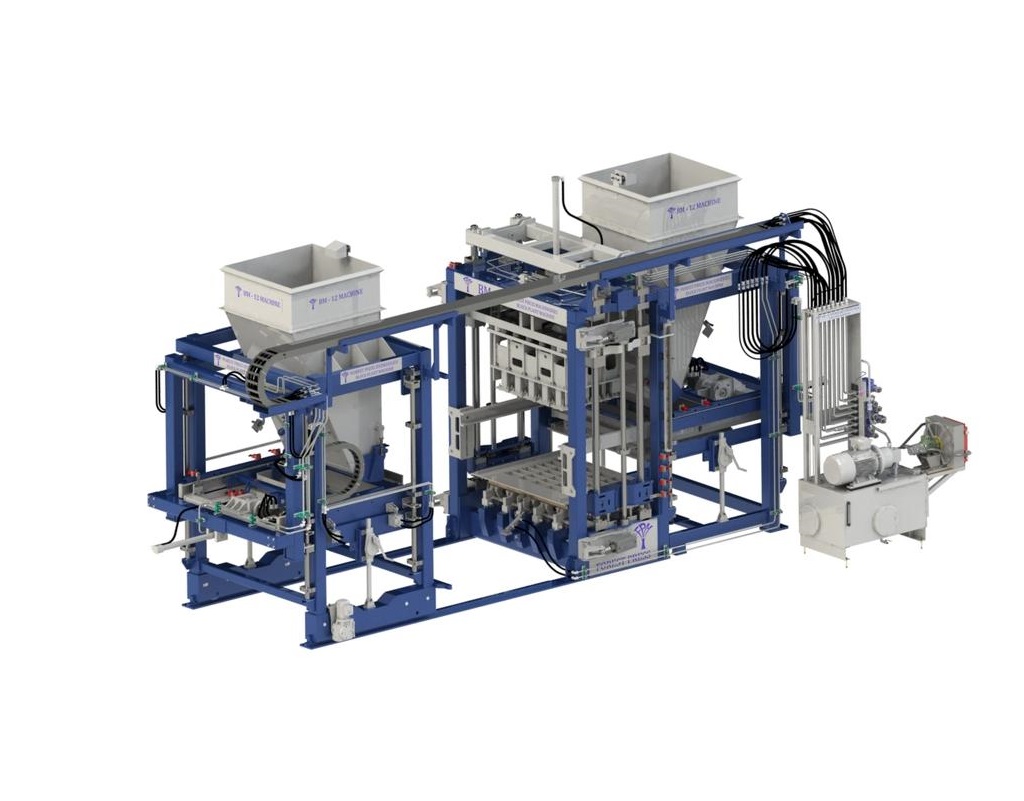

- High advanced technology machine

- Pallets are automatic feed

- Green Product handled by V_belt conveyor to prevent shocks

- Pallets are stacked in Elevator

- Product sent to cure chamber automated finger car system

- Cycle time 15-18 secs

-

Pallet size - 1400 x 900 x 12/45 - steel/wooden

- Synchronized vibration by Servo motor

- Max/min product height 250/25

- Automatized packing system can be used

- To avoid human delays

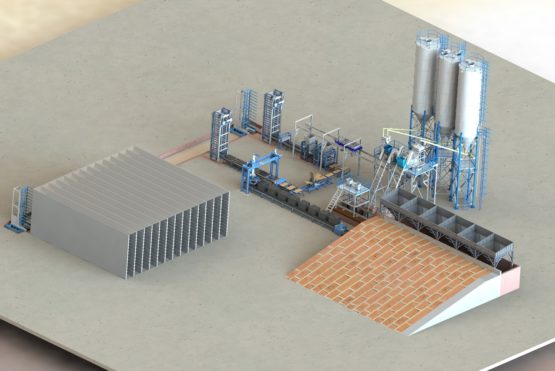

- U type of system to minimize shed area

- Green product & Dry product can be handled separately

- Flying bucket concrete system

- Agitator for fast filling

- Multicolored dosing

- Palletizer and offloading conveyor used to take out dry product without running wet line

- Finished product treatment washing, tumbling, shot blasting can be added as per customer requirement

Main Assembly

- Base Mix

- Face Mix

- Walking Beam Conveyor

- Stone Brush

- Elevator

- Finger car

- 360 deg rotation transfer car

- Curing Chamber

- Air circulation system

- Lowerator

- Walking Beam Conveyor

- Board Scrapper

- Board Brush

- Pallet turner

- Hydraulic cuber

- Out Put Frame Conveyor

- Cross Conveyor

- Board Hopper

- Board feeder

- Oil spray system

- Board Stopper

- Pallet offloading conveyor

- Palletizer